In-mold resin pressure measuring system

Advantages of introduction

1. Detection of defects in mold products

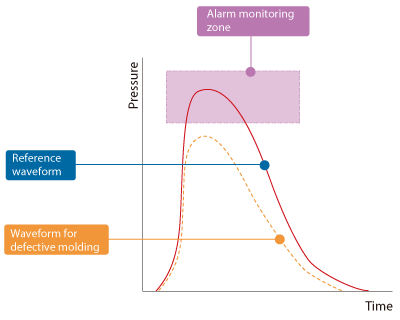

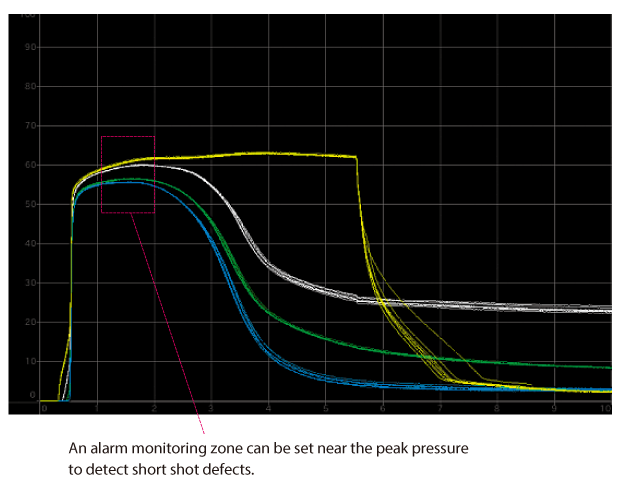

By utilizing alarm signals triggered by the deviation of the measurement waveform with respect to the reference waveform, the system detects molding defects including short shot and over pack.

Examples of action to take in the event of detecting a defective product

- ・ Prevention of continuous ejection of defective products (stoppage of molding machine)

- ・ Sorting of defective products (automatic sorting by means of ejector or the like)

2. Setting conditions for molding when the molding machine or molding site has changed

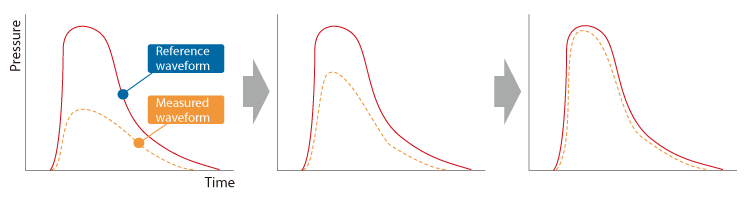

By saving the waveform of a good-quality product (reference waveform) and performing molding to make the same waveform, it is possible to produce mold products with the same quality.

Example of change of conditions

- ・ Change of overseas transfer destination

- ・ Change of molding machine (manufacturer, capability, method)

- ・ Change of environment (factory, transfer to external party)

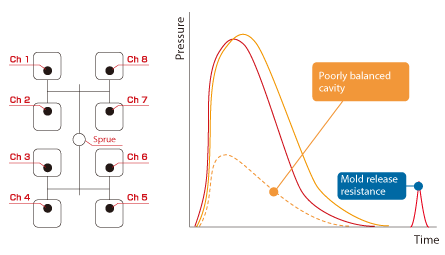

3. Analysis of mold structure and flow analysis

By analyzing the elapsed time and the pressure, it takes for the resin to arrive at the sensor, it is possible to check the degree of completion of the mold.

Matters that can be checked through flow analysis

- ・ Check of runner balance and gate balance

- ・ Check after modification of runner and gate

- ・ Verification of flow analysis result

- ・ Check of mold release resistance value

4. Check of relationship between in-mold resin pressure waveform and molding defect

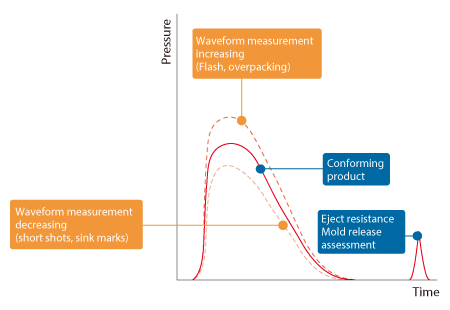

With respect to the waveform of a good-quality product (reference waveform), it is possible to infer the details of molding defects based on the pressure waveform.

Details of defects that can be inferred from pressure waveform

- ・ Waveform measurement value

Increase → Flash, overpacking

Decrease →Short shots, sink marks - ・ Protruded waveform

Large → Large release resistance

Small → Small release resistance

- ・ Waveform measurement value

Measurement waveform

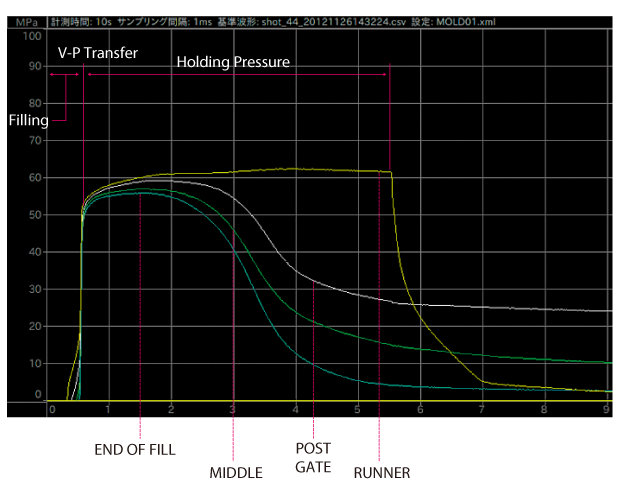

It is possible to check the condition of the pressure inside the mold in real time by displaying it as a waveform on a dedicated measurement software. By saving the waveform of a good-quality product as the “reference waveform,” it is possible to use that data for condition setting in a different molding environment. By setting an alarm monitoring frame, the software effectively monitors defects, such as short shot and overpack, in mass-production.

Reference waveform and waveform of pressure inside mold

Overlapped pressure waveform

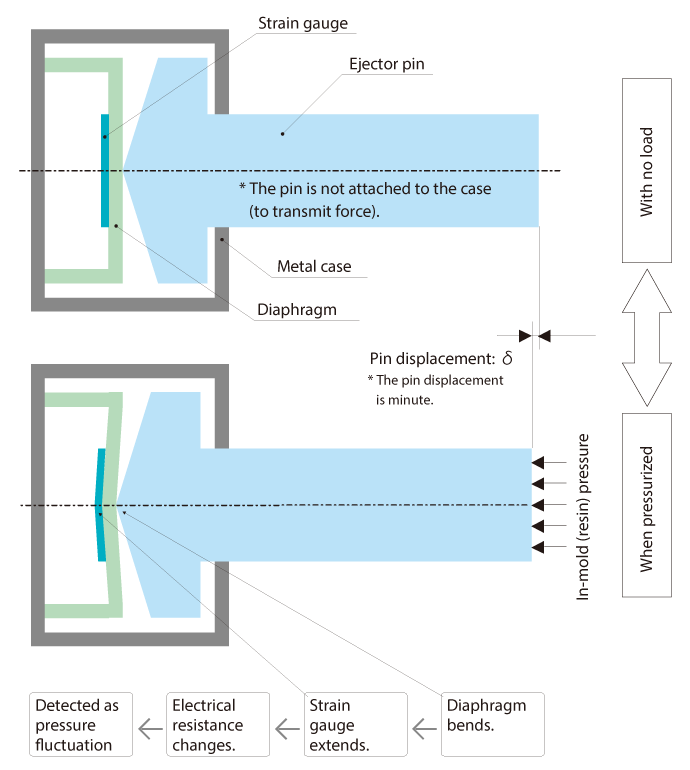

Measurement principle

The resin pressure inside the mold is received by the strain gauge via the ejector pin, output as electric signals, and arithmetically processed by the measurement amplifier. The result of the arithmetic processing is displayed as a pressure waveform on a dedicated measurement software.

Measurement principle (simplified diagram)

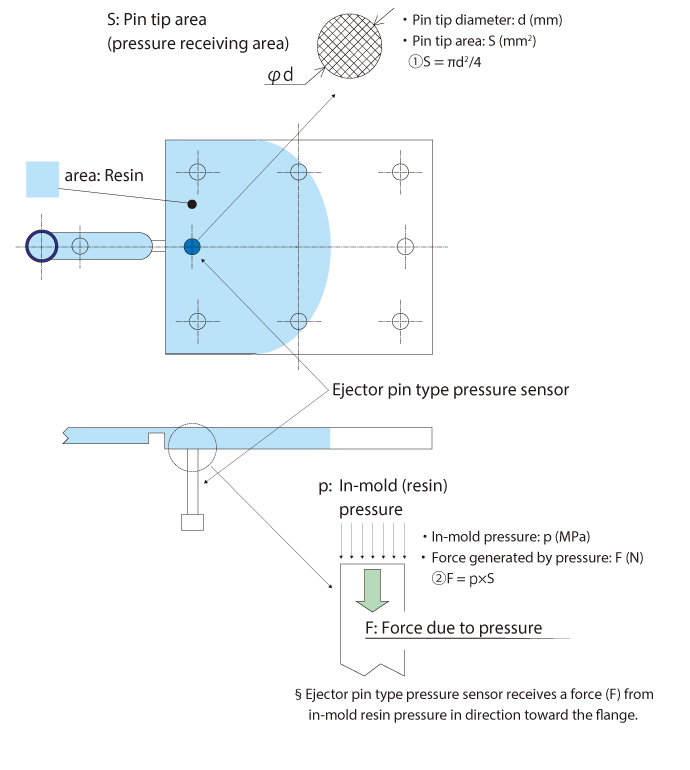

Force received by sensor

Types of measurement amplifiers and sensors

Pressure measurement amplifier MPS08B

- As a standalone amplifier, this product can conduct monitoring, alarm output, and recording of measurement data.

- Measurement data can be saved in a USB memory stick.

- Up to four amplifiers can be connected to each other, and simultaneous measurement in a maximum of 32 channels is possible.

- The display language can be switched between Japanese and English on the measurement software.

- With the volume and weight reduced by 40% in comparison with earlier models, this product can be installed with a magnet.

- Equipped with RS485 interface, this product is compatible with MODBUS communication protocol.

Inline pressure measuring unit

MPS01A- A low-priced type for inline use

- Digital display that is easily visible even in a busy mass-product site

- In addition to the conventional defect detection function, a variety of functions are equipped.

- Conforming to RS485 communication standard, this product is capable of remote monitoring.

Pressure sensor – ejector pin type

SSE series- Due to its ejector pin shape, it can replace an existing ejector pin. (*2)

- The pin section can be cut in accordance with the mold.

- The order can be placed by specifying the overall length of the pin section.

*1 The product needs to be combined with the pressure measurement amplifier MPS08B or MPV04.

*2 Machining such as flange cutting to prevent rotation is not possible.

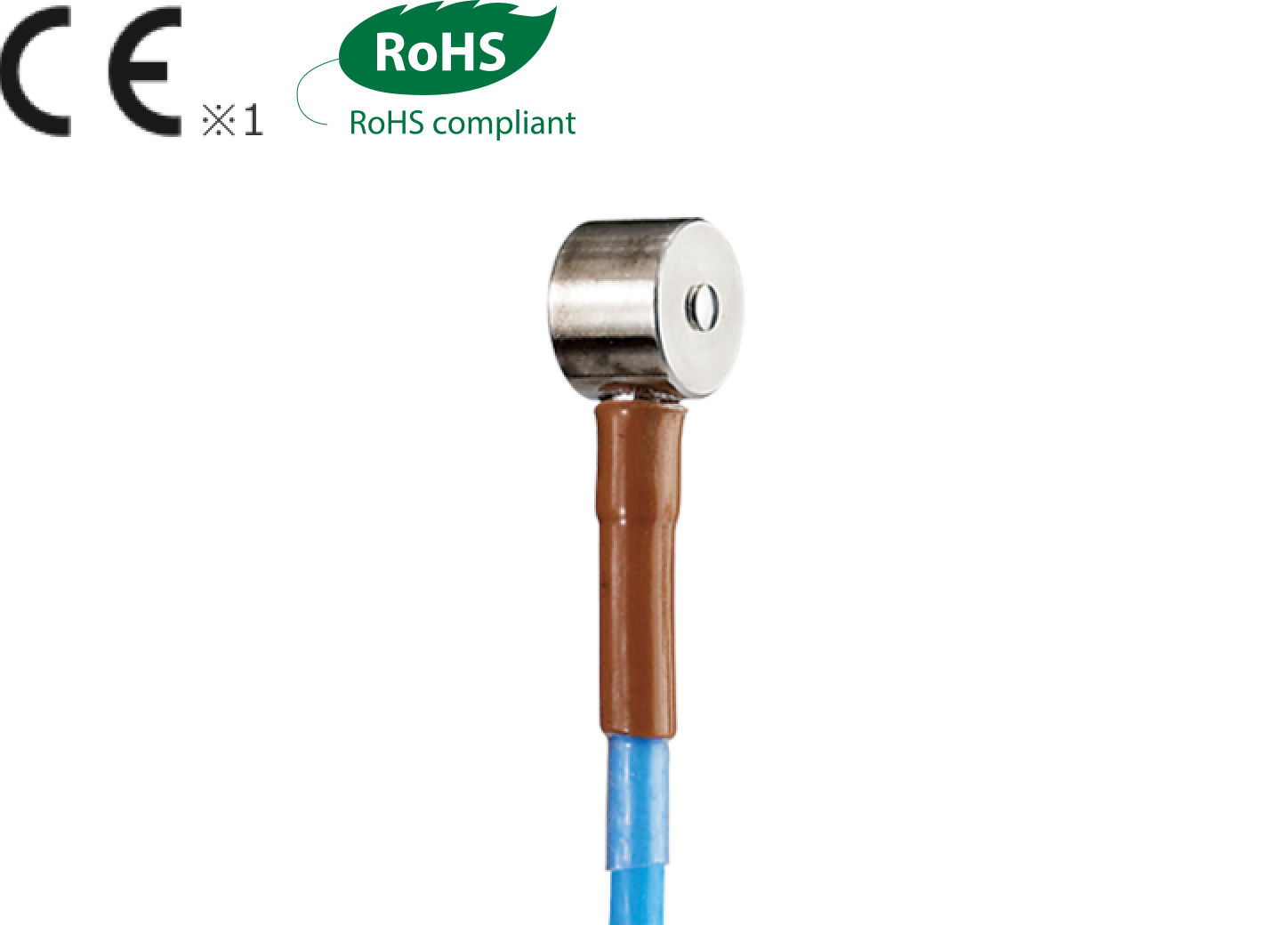

Pressure sensor – button type SSB series

- As this performs measurement after it is positioned right beneath the ejector pin, the ejector pin in use can be used as is.

- This product can be applied to a “small-diameter pin,” “square pin,” “pin with irregular tip shape,” and “flange cut pins,” which cannot be measured by the ejector pin type.

- We offer large-capacity products of 4 kN and 16 kN types that are applicable to ejector pins with a diameter of φ4 to φ14.

- We also offer heat-resistant products that are applicable to a mold temperature of up to 200˚C.

*1 The product needs to be combined with the pressure measurement amplifier MPS08B or MPV04.

Pressure sensor – button type for junction boxes with cable storage space SCB series

- The employed φ1.1 mm sensor cable can be housed in the wire-housing type junction box, which allows it to do a constant measurement connection to mold.

- We offer low-capacity models with a width of 3.5 mm and a pin diameter of φ0.3 to φ1.0 mm that can be applied to the low-pressure range with a recommended measurement range of 5 to 10 N (rating capacity: 10 N).

- We also offer heat-resistant products that are applicable to mold temperature of up to 200˚C.

- *1 It is necessary to combine this product with the pressure measurement amplifier MPS08B.

- *2 The only compatible amplifier is MPS08B.

- ・For information on direct pressure sensors, refer to “Injection molding monitoring system.”

For detailed product information, download the material from the following link and check it.

Download the material