Injection molding monitoring system

MVS08 injection molding monitoring system

- Q1. How is measurement data saved when three MVS08 units are connected together?

A1.Data is saved for each MVS08 unit as a file containing the following in the file name:

MVS08 unit: 1st unit: MODULE1, second unit: MODULE2, 3rd unit MODULE3.

- Q2. Is it possible to edit waveforms saved to a PC?

A2. Measurement data is saved as CSV files. These files can be edited.

- Q3. What are the minimum PC requirements?

A3.Operating system (Japanese language compatible): Windows 7 (32 bit/64 bit), Windows 8 (32 bit/64 bit), Windows 8.1 (32 bit/64 bit), Windows 10 (32 bit/64 bit); processor: Intel CPU Core i5 or higher; memory: 4 GB or more; other: Ethernet port. .NET Framework 4.0 or later must be installed.

- Q4. Can I connect by wireless LAN?

A4. The warranty does not cover wireless LAN connection.

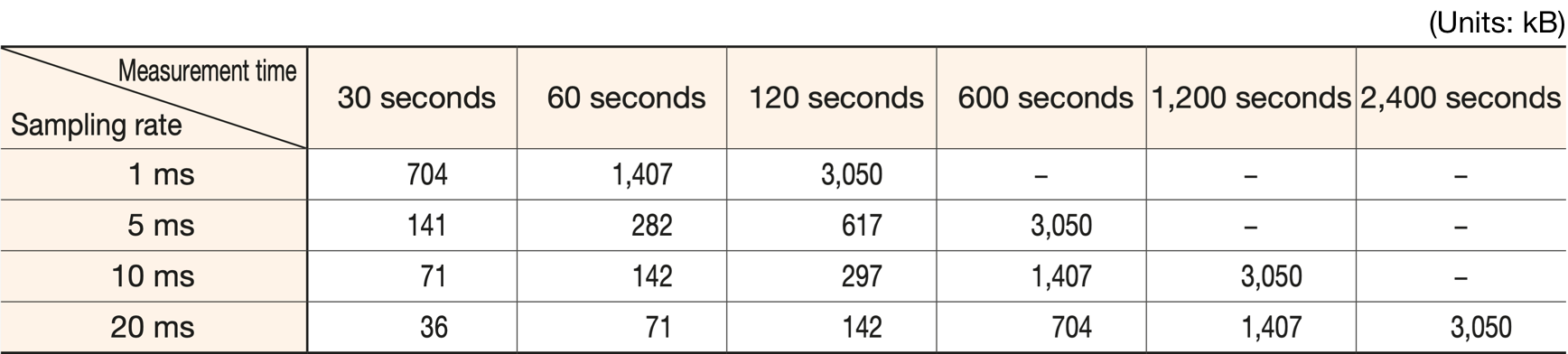

- Q5. What are the typical volumes of the saved data?

A5. The volume of the waveform data will vary depending on sampling rate and measurement time.

Refer to the following table for a guide:

- Q6. What happens when the PC runs out of available disk space?

A6. The waveform will appear on the measurement screen. However, once the hard disk capacity falls below 10%, the “Available disk space” display on the measurement screen will turn red, and data can no longer be saved. We recommend transferring data elsewhere at frequent intervals.

- Q7. Can I use any commercially available LAN cable?

A7. Depending on specifications, a certain cable may be susceptible to noise. The recommended Futaba cable is a 2 m long Cat 7 shielded cable.

- Q8. Can I view waveforms on the molding machine monitor?

A8. The MVS08 can only be connected to a PC. It cannot be connected to devices such as molding machines or data loggers.

- Q9. Can I connect the EPV-001?

A9. No.

- Q10. Can I connect a flow rate measuring system?

A10. No.

- Q11. How can I load information from an injection molding machine (external device)?

A11. With a molding machine, data can be loaded using the dedicated cable, provided that information such as injection pressure, holding pressure, and screw position is in the form of a voltage output (in the range 0 to 10 V DC). (Interface cable product code: WCI0130-2P N-MVS08 catalog page 77)

- Q12. Does molding process monitoring also allow defect signals to be output during mass production?

A12. An NPN open collector signal is output in the same way as with the existing measuring amplifier.

- Q13. Since this uses a LAN connection, is it possible to save data to an in-house server?

A13. Data can be saved on an in-house server using a hub. (Consult with your company’s system administrator for IP address settings.)

- Q14. Communication isn’t possible, even after setting the IP address as described in the manual.

A14. Disable firewalls and anti-virus software, then restart the PC and try again.