Mold surface temperature measuring system

- Q1. What are the benefits gained from adopting this measuring system?

A1. Measuring mold temperatures close to the cavity has useful applications in monitoring molding conditions, quality control, and defect screening. It also makes it possible to check the stability of mold temperatures, refine discarded shot management, and reduce resin waste.

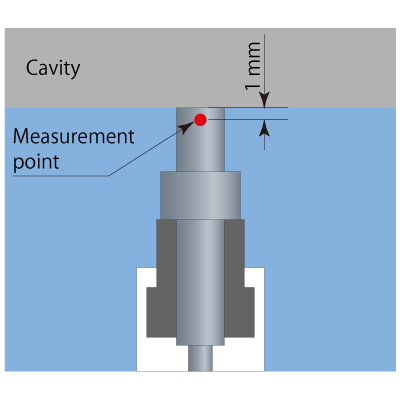

- Q2. Where in the cavity is the temperature measured?

A2. The contact used to detect temperature is located within 1 mm from the sensor tip. The sensor is mounted flush with the cavity surface to measure temperatures at a point inside the mold 1 mm from the cavity surface.

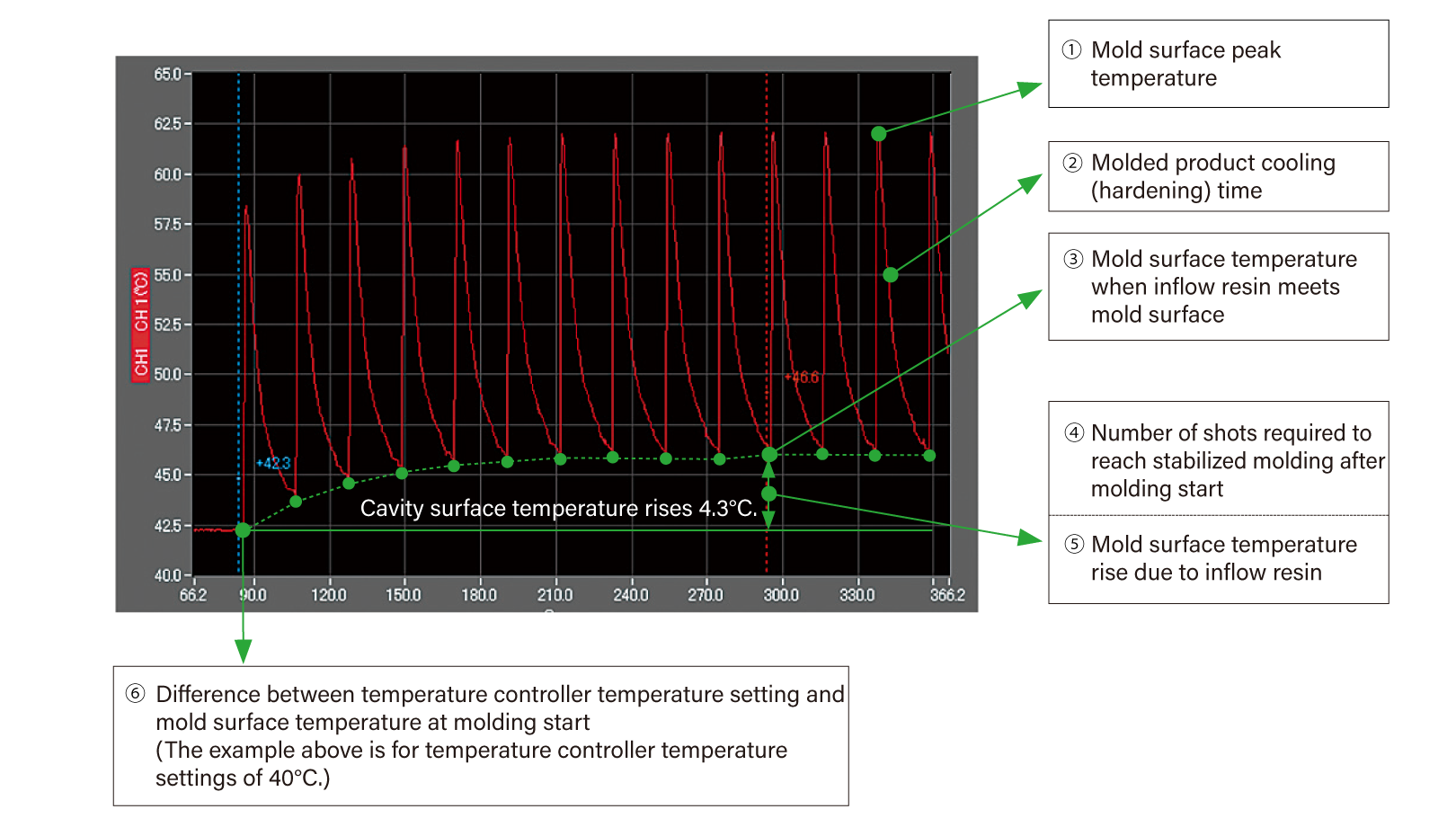

- Q3. What does the waveform show?

A3. In mass-production molding, checking points ② and ③ below reveals whether stabilized molding has been attained (using commercially available measuring instruments and software).

- Q4. What kind of a profile is a flush-mount profile?

A4. This means the sensor is installed with the sensor tip flush with the cavity surface (“exposed mounting”).

- Q5. Is additional machining possible?

A5. STF04.0X08.0X026 can be ground over a length of 0.01 mm to 0.02 mm from the tip. However, the tip profile cannot be machined or made curved or diagonal.

STF01.0X11.5X18.5 is not available for additional machining.

- Q6. Why are type K thermocouples used?

A6. Type K thermocouples are the most widely used thermocouples and inexpensive.

- Q7. What do I need to purchase to introduce the system?

A7.

- (1) Mold surface temperature sensor

- (2) Mold surface temperature sensor adapter cable (1 m or 2 m cable)

(1) and (2) can be used to connect to commercially available measuring instruments. - (3) Retaining screw (M8 or M10): Slot-head screw for mounting sensors to the mold ( catalog page 49)

- (4) Sensor securing wrench: Tool used to tighten and loosen the retaining screw (3) ( catalog page 49)

- (5) Sensor removal wrench: Tool used to extract sensors fixed to the mold ( catalog page 49)

※Items (1) to (4) are required at the system introduction.

※(5) is not required to remove sensors that can be removed by pushing gently from the sensor tip.Note that the retaining screw (3) and sensor securing wrench (4) are not required if sensors are mounted on the mold by a method that does not use screws.

※Note that the size of the retaining screw, sensor securing wrench, and sensor removal wrench are different for STF04.0X08.0X026 and STF01.0X11.5X18.5.

- Q8. Can sensors be used without purchasing the mold surface temperature sensor adapter cable?

A8. A thermocouple connector is fitted to the sensor, but you can extract the thermocouple wire by disassembling this. If this is connected directly to the measuring instrument terminal board, measurement is possible without an adapter cable.