Case Studies

Search by Categories

-

Succeeded in reducing inspection workload, resulting in an annual savings of 2.3 million yen

Download the materialーKAWACHO Co., Ltd. ー

The company strengthened its inspection system following the outflow of short shots, but this required a great deal of inspection time. This is a case study of how an in-mold measurement system was introduced to reduce inspection workload that could not be solved by image inspection equipment or the molding machine monitoring function.

-

Visualization of manufacturing process, reform under the site initiative

Download the material- Tamagawa Microtep Co., Ltd. -

This is a manufacturing reform that started at a molding site. This material introduces a case example in which improvements including visualization of the causes of defects, mold modification based on data, defect prediction, and visualization of mold maintenance timing have been achieved through data utilization by means of MOLD MARSHALLING SYSTEM and MT method.

-

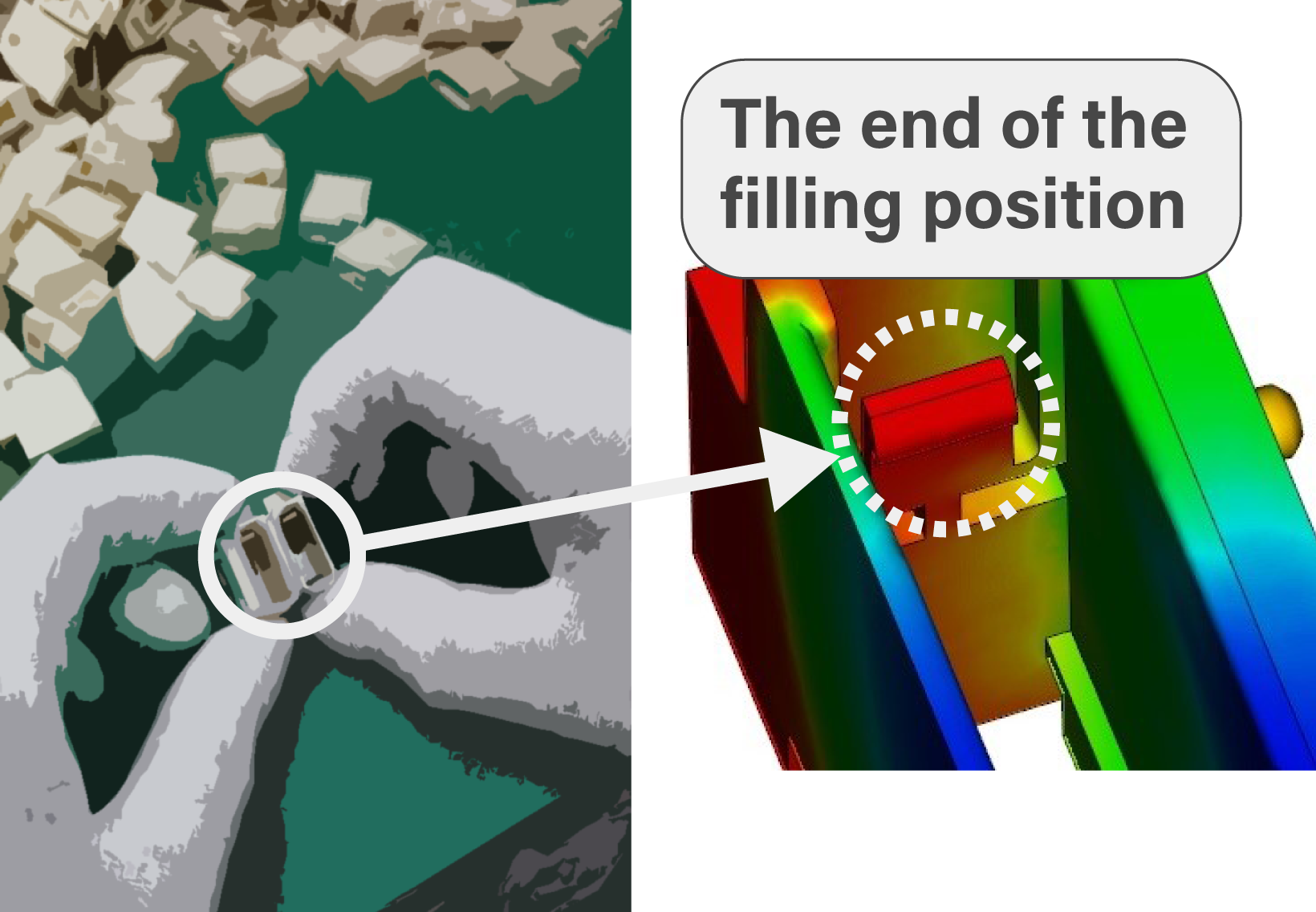

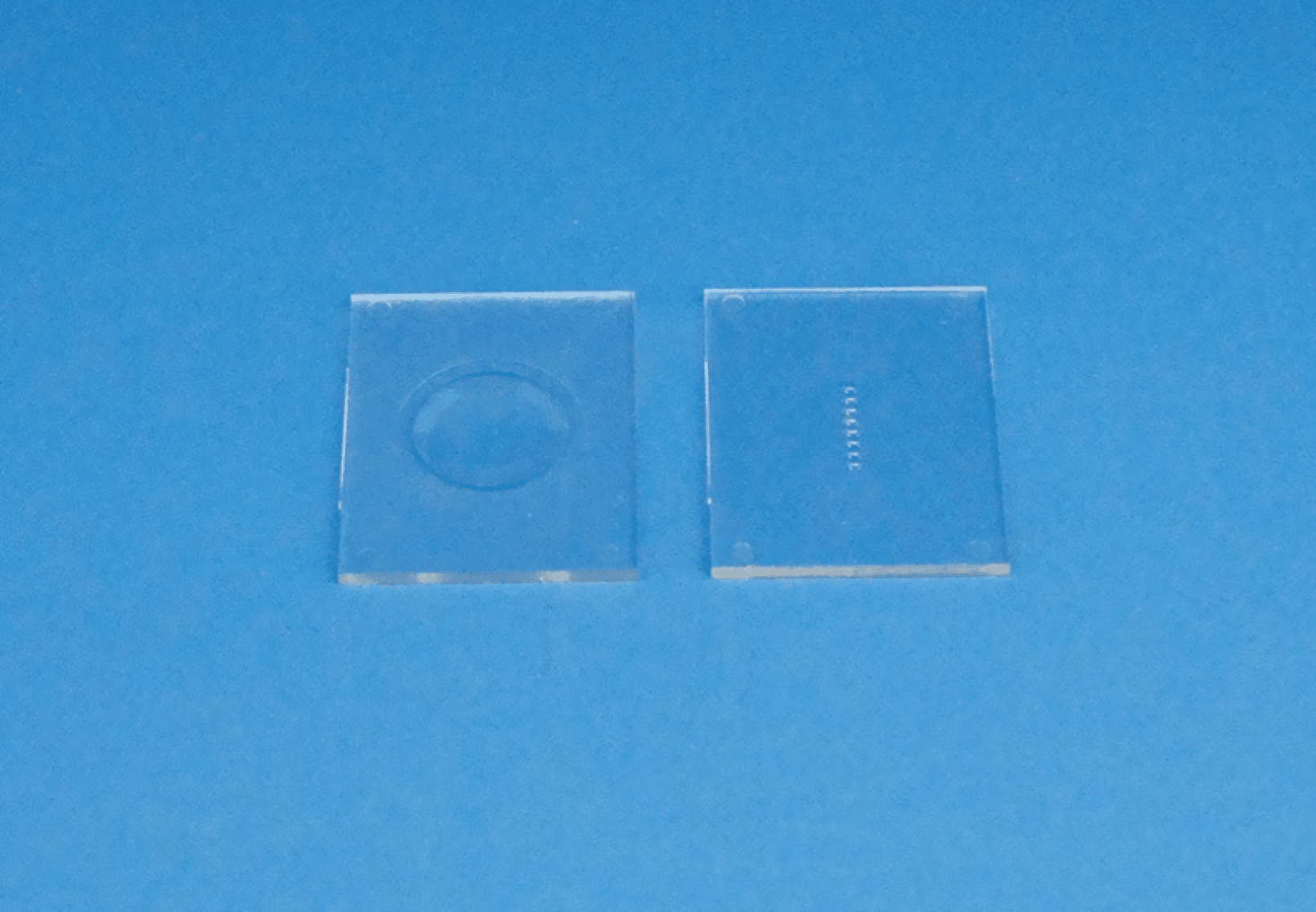

Digital engineering applied to precision parts

Download the material- Ikegami Mold Engineering Co., Ltd. -

The company boasts excellent mold technologies of “mold making guaranteeing μ” and “astonishing surface roughness of Ra 1 nm.” This material introduces case examples of “visualization of resin inflow timing and pressure peak arrival timing in family mold molding” and “lens connector PASS/FAIL judgment through combined measurement and AI analysis.”