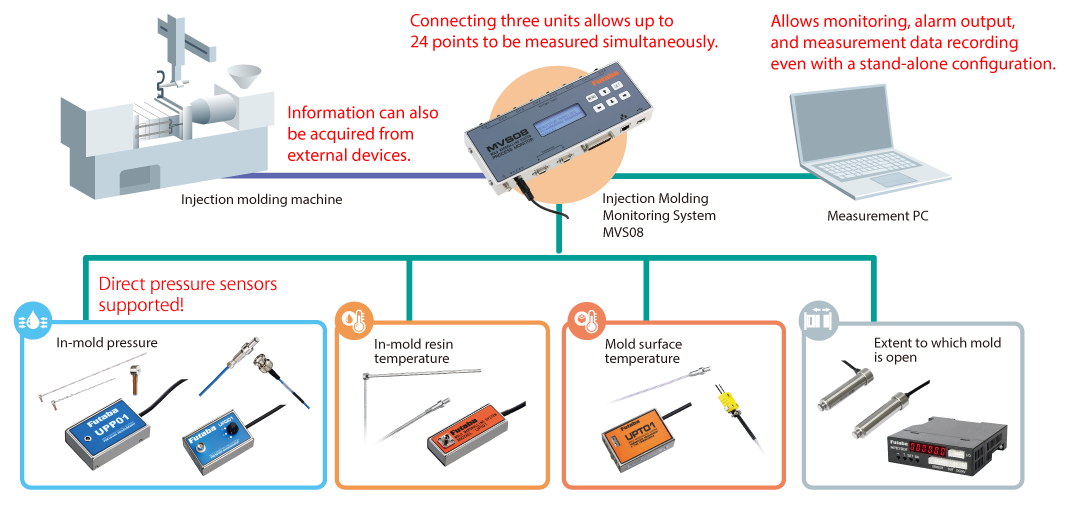

Injection molding monitoring system

Advantages of introduction

Multilateral analysis in which multiple pieces of information are integrated

Information including in-mold pressure, in-mold resin temperature, and mold surface temperature, as well as information on measurement instruments and injection molding machines from other manufacturers is imported as analog voltages and displayed with the time axis synchronized to achieve more advanced analysis. The displayed waveform allows alarm signals in the set monitoring frame to be output and the measurement data to be recorded, making it possible to use the product for mass-production monitoring.

-

Simultaneous monitoring at up to 24 points

By connecting three pieces of MVS08, it is possible to measure information including “in-mold pressure,” “in-mold resin temperature,” and “mold surface temperature” at up to 24 points in real time. The product can solve the challenges you face concerning multi-point measurement such as installation of various sensors in cavities of multi-piece mold.

Standalone function that is useful in mass production

Even in a standalone condition in which connection to a PC is not made, the product can output alarms and record measurement data. As it is possible to select a set of measurement conditions from 10 measurement condition sets stored inside, it is not necessary to connect to a PC to change the measurement conditions. Connecting a USB memory stick to the body of this product makes all data automatically saved. Therefore, it is possible to conduct continuous recording for long hours even without a PC for data storage use as used in conventional models.

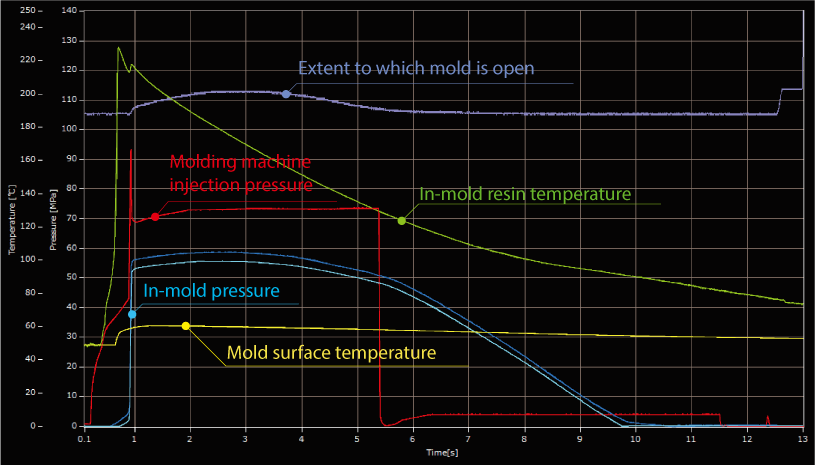

Measurement waveform

As the product can import pieces of information including in-mold pressure, in-mold resin temperature, mold surface temperature as well as information on measurement instruments and injection molding machines from other manufacturers, and display them with the time axis synchronized, it can be used for more advanced analysis.

-

Measurement waveform displayed by the injection molding monitoring system

Types of measurement amplifiers and sensor

-

Injection molding monitoring system MVS08

- In addition to in-mold pressure, in-mold resin temperature, and mold surface temperature, it is also possible to import information of external devices as analog voltage.

- The dedicated measurement software can display those pieces of information by easily integrating time axes.

- The overlapping function, alarm monitoring frame setting function, and control signal output function are equipped.

- When three pieces of the product are connected, it is possible to conduct simultaneous measurement in up to 24 channels.

- Even in a standalone condition, it is possible to conduct monitoring, alarm output, and data recording.

- On the measurement software, it is possible to change the display language among Japanese, English, Chinese, and Korean.

-

Direct pressure sensor SPF04.0×08.0×030

- The product can measure the pressure inside the mold at a high accuracy (nonlinearity: ±1.0%F.S.).

- Flush-mount shape that has achieved highly flexible installation position

-

Mold open measurement sensor

MEL series- The product can measure the mold opening amount on the parting line at a micron accuracy.

- As this is a magnetic induction type product, it can conduct measurement at a high accuracy even in a high-temperature environment.

- The product can be embedded in the mold of an injection molding machine or press machine.

-

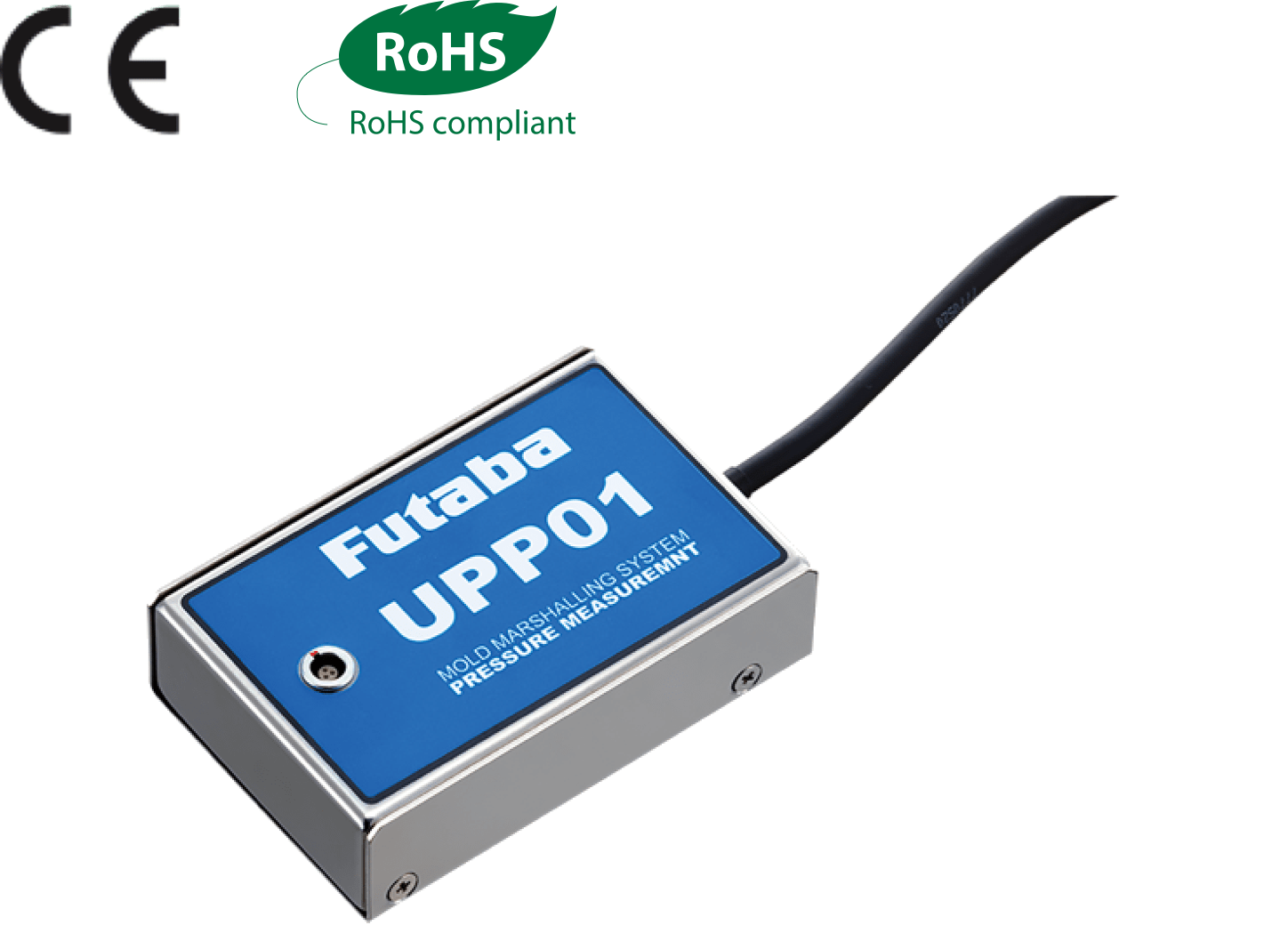

Pressure preamplifier for MVS08

UPP01A- This is a pressure preamplifier for MVS08.

- A pressure sensor can be connected to a piece of this product without using an existing pressure measurement amplifier.

-

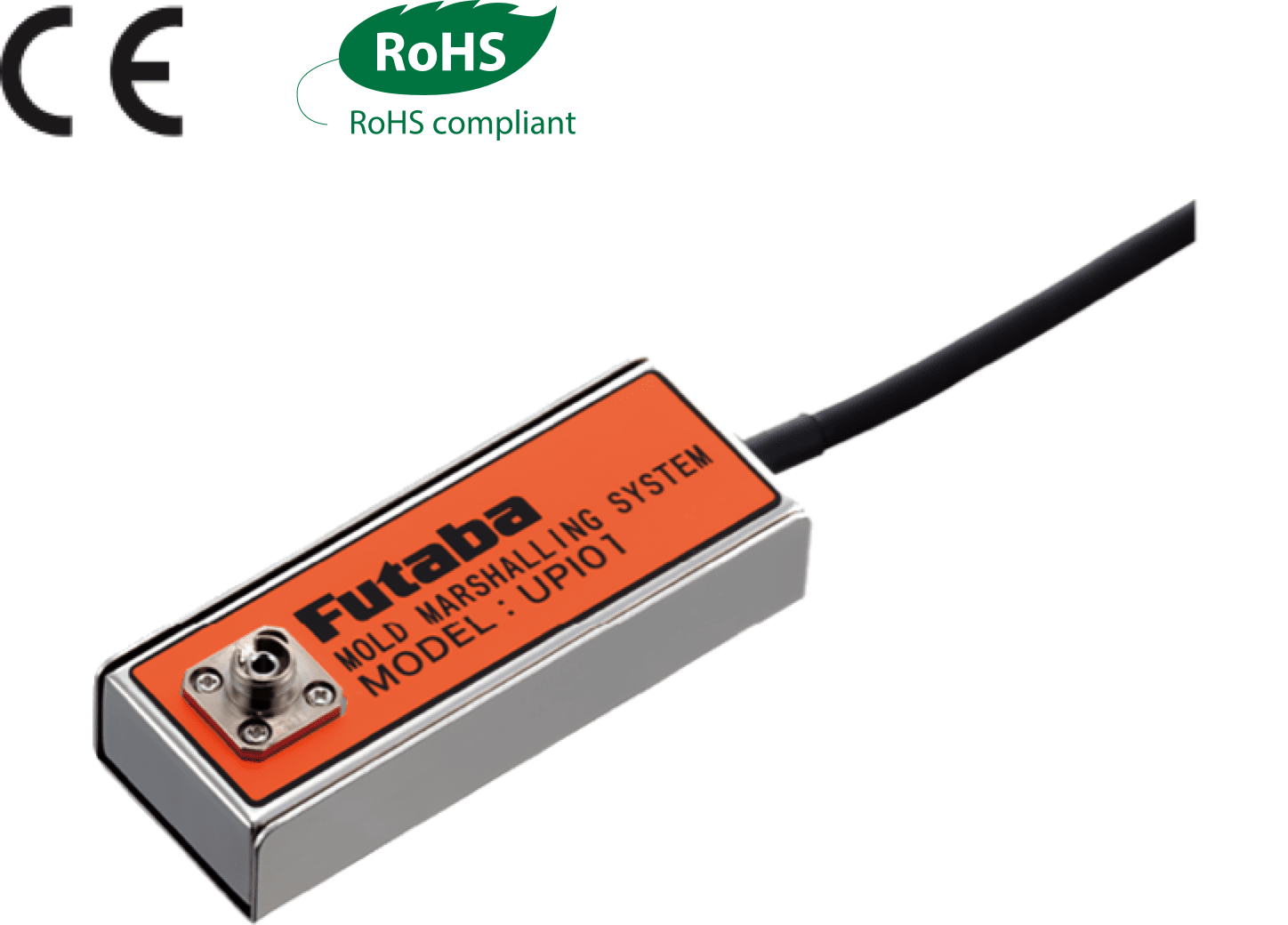

Resin temperature preamplifier for MVS08

UPI01A- This is a resin temperature preamplifier for MVS08.

- A resin temperature sensor can be connected to a piece of this product without using an existing resin temperature measurement amplifier.

-

Mold surface temperature preamplifier for MVS08

UPT01A- This is a mold surface temperature preamplifier for MVS08.

- A mold surface temperature sensor can be connected to a piece of this product without using a commercially-available signal converter.

-

Direct pressure preamplifier for MVS08

UPQ01A- This is a direct pressure preamplifier for MVS08.

- One direct pressure sensor can be connected to each one of preamplifier.

-

Mold open preamplifier for MVS08

MPD200F- This is a mold open preamplifier for MVS08.

- One mold opening measurement sensor can be connected to each one of preamplifier.

Sensor that can be connected to MVS08

-

Pressure sensor – ejector pin type SSE series

- Due to its ejector pin shape, this product can replace the existing ejector pin. (*2)

- The pin section can be cut in accordance with the mold.

- The order can be placed by specifying the overall length of the pin section.

- *1 The product needs to be combined with the pressure measurement amplifier MPS08B or MPV04.

- *2 Machining such as flange cutting to prevent rotation is not possible.

-

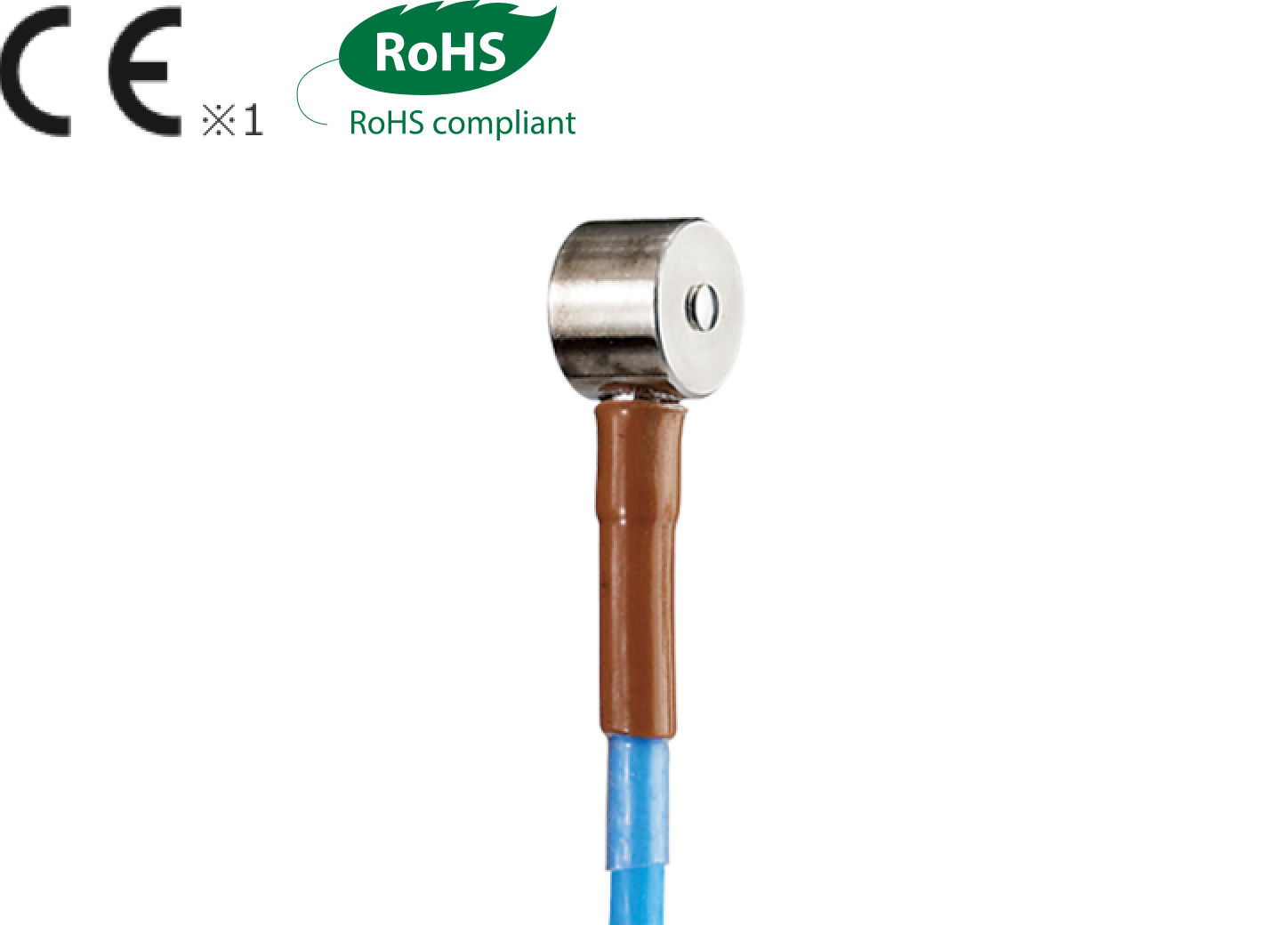

Pressure sensor – button type SSB series

- As this performs measurement after it is positioned right beneath the ejector pin, the ejector pin in use can be used as is.

- This product can be applied to a “small-diameter pin,” “square pin,” “pin with irregular tip shape,” and “pin with cut collar,” which cannot be measured by the ejector pin type.

- We offer large-capacity products of 4 kN and 16 kN types that are applicable to ejector pins with a diameter of φ4 to φ14.

- We also offer heat-resistant products that are applicable to mold temperature of up to 200˚C.

- *1 The product needs to be combined with the pressure measurement amplifier MPS08B or MPV04.

-

Pressure sensor – button type for junction boxes with cable storage space SCB series

- The employed φ1.1 mm sensor cable can be housed in the wire-housing type junction box, which allows it to do a constant measurement connection to mold.

- We offer low-capacity models with a width of 3.5 mm and a pin diameter of φ0.3 to φ1.0 that can be applied to a low-pressure range with a recommended measurement range of 5 to 10 N (rating capacity: 10 N).

- We also offer heat-resistant products that are applicable to mold temperature of up to 200˚C.

- *1 It is necessary to combine this product with pressure measurement amplifier MPS08B.

- *2 The compatible amplifier is MPS08B only.

-

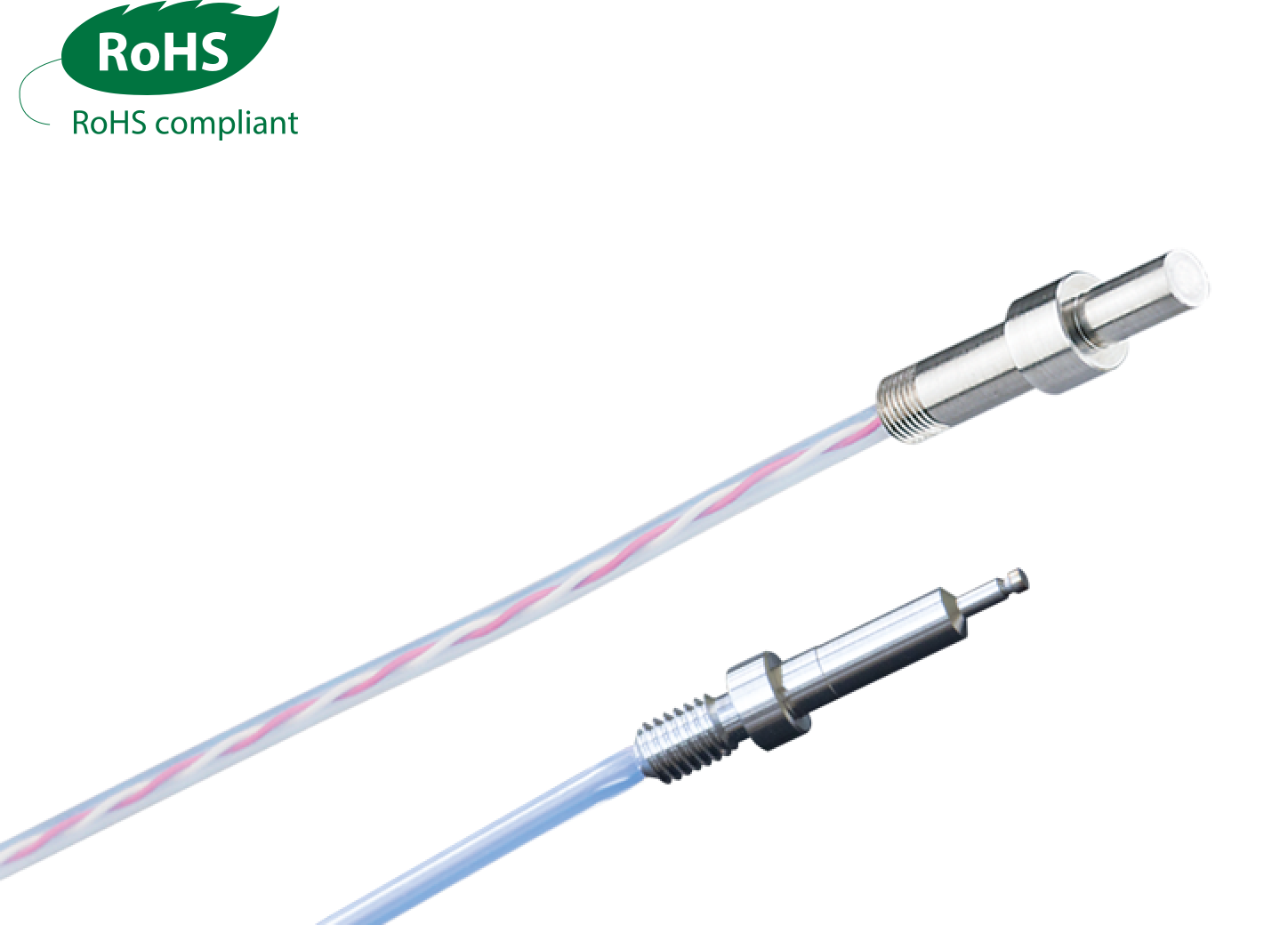

Resin temperature sensor – ejector pin type EPSSZL series

- Infrared ray detection type with optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- Resin temperature in the range of 60˚C to 430˚C can be measured.

- The ejector pin shape allows easy incorporation in a mold. (*1)

- With the minimum tip diameter of φ1.7 mm, the product is also applicable to small-size mold products.

*1 Machining such as flange cutting to prevent rotation is not possible.

-

Resin temperature sensor – flush-mount type EPSSZT series

- Infrared ray detection type with optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- Resin temperature in the range of 60˚C to 390˚C can be measured.

- Flush-mount shape that has achieved highly flexible sensor installation position

-

Mold surface temperature sensor

STF- As a sensor for injection molding mold, the product boasts a rigid design that withstands a mold temperature of up to 220˚C and resin pressure of up to 150 MPa.

- Due to the employment of a K thermocouple, this product allows a general-purpose temperature measurement instrument and a data logger to conduct measurement, which enables the introduction of the sensor at low cost.

- With the minimum tip diameter of φ1, the product can also be applied to small-size mold products.

- For detailed product information, download the material from the following link and check it.