Flow front detection system

Advantages of introduction

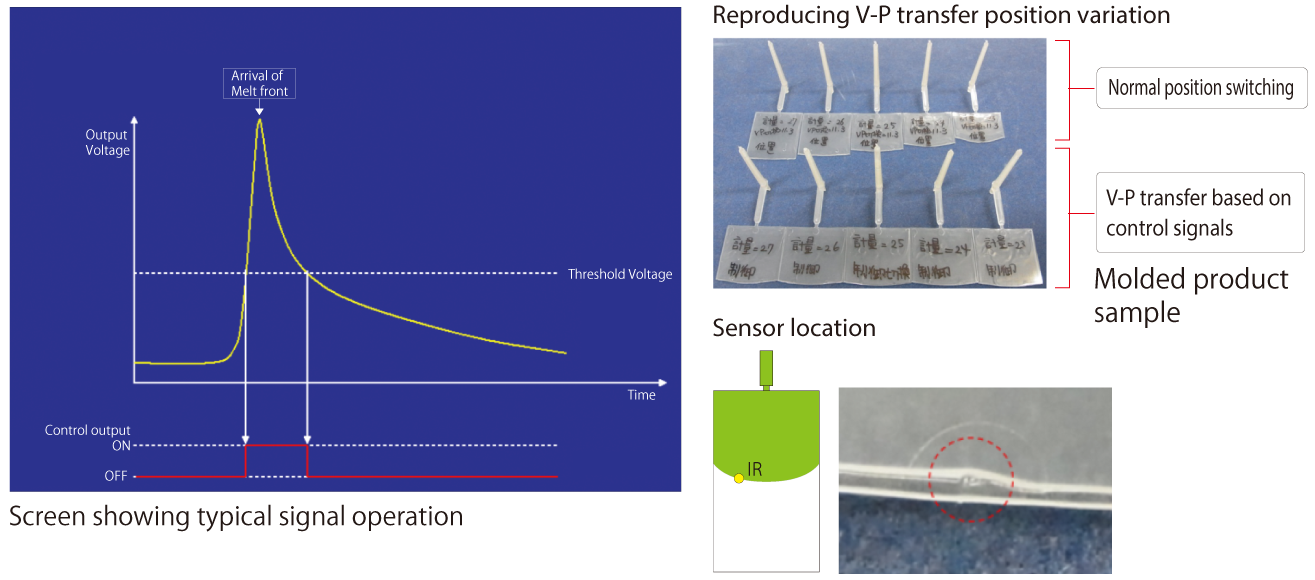

Control of V-P transfer timing

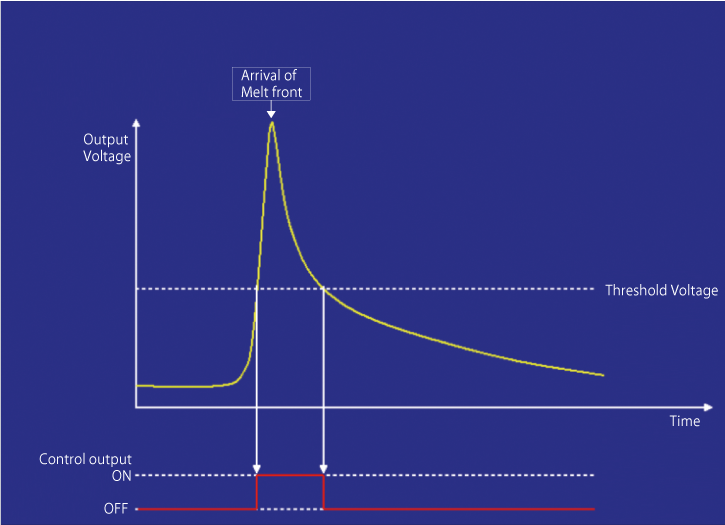

In combination with an 8-ms (63.2% response) high response sensor, the product instantly detects the arrival of resin and outputs a control signal. By controlling the variation of the V-P transfer position caused by wearing of screws and other components of the molding machine by using the passage of resin at the tip of the sensor as a trigger, it is possible to control the timing at a constant level.

Measurement waveform

By installing this product at the end of the mold product, it can be utilized for control of V-P transfer timing and the detection of short shot.

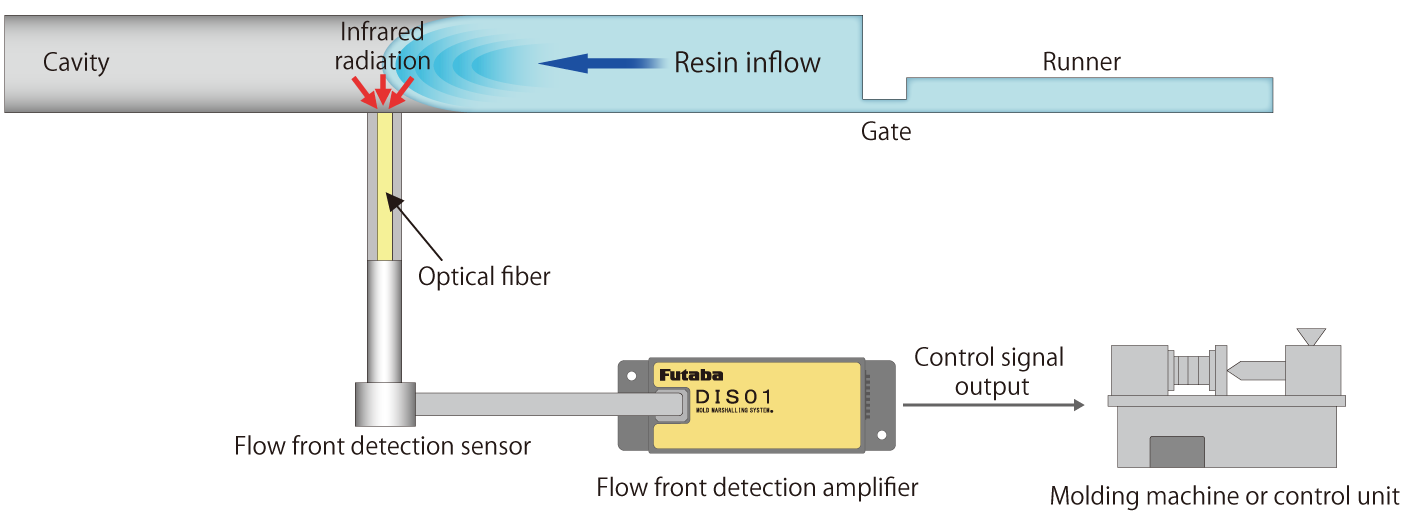

Measurement principle

The product instantly detects the arrival of the flow front of resin by means of infrared ray. It also performs open collector output and indicates the arrival via an LED lamp at the same time.

Types of sensors

Flow front detection amplifier

DIS01- Due to the infrared ray detection method, which is resistant to disturbance, this product achieves noise resistance at a high level.

- The threshold for control signal output can be freely adjusted in the range of 0 to 13 V.

Flow front detection sensor

DISSZL series- Infrared ray detection method that uses optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- The ejector pin shape allows easy incorporation in a mold. (*1)

*1 Machining such as flange cutting to prevent rotation is not possible.

Flow front detection sensor

DISSZT series- Infrared ray detection method that uses optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- Its flush-mount shape has achieved a highly flexible sensor installation position.

- Resin temperature can be measured in the range of 60˚C to 390˚C.

For detailed product information, download the material from the following link and check it.

Download the material