Mold surface temperature measuring system

Advantages of introduction

Reduction of abandoned shots

As it is possible to determine the start of molding to the point where the mold temperature stabilizes based on data, the abandoned shots can be minimized and the environmental load can be reduced (reduction of waste resin). For example, in a molding site where molding with “the first 30 shots from the start of molding are abandoned” or the like is practiced, if it can be confirmed that the mold temperature has stabilized at 15 shots, the volume of abandoned shots can be reduced.

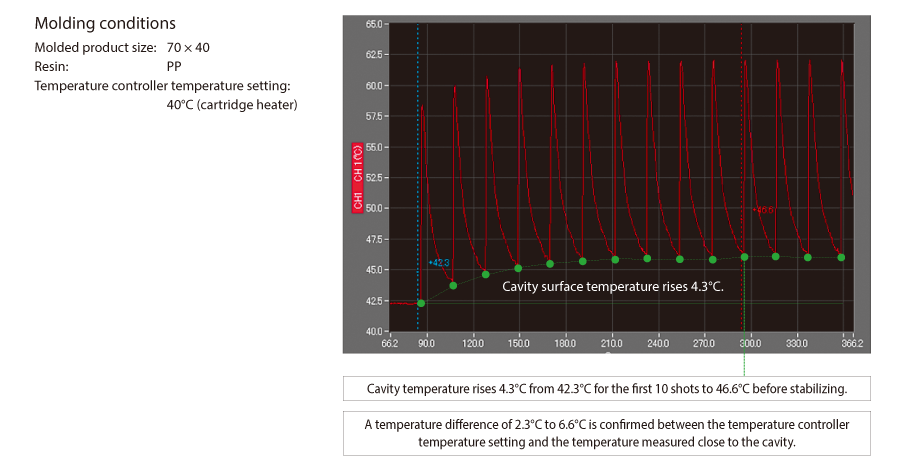

Molding conditions

Mold product size: 70×40

Resin: PP

Temperature controlling machine setting temperature: 40˚C (cartridge heater)Information that can be read from waveform

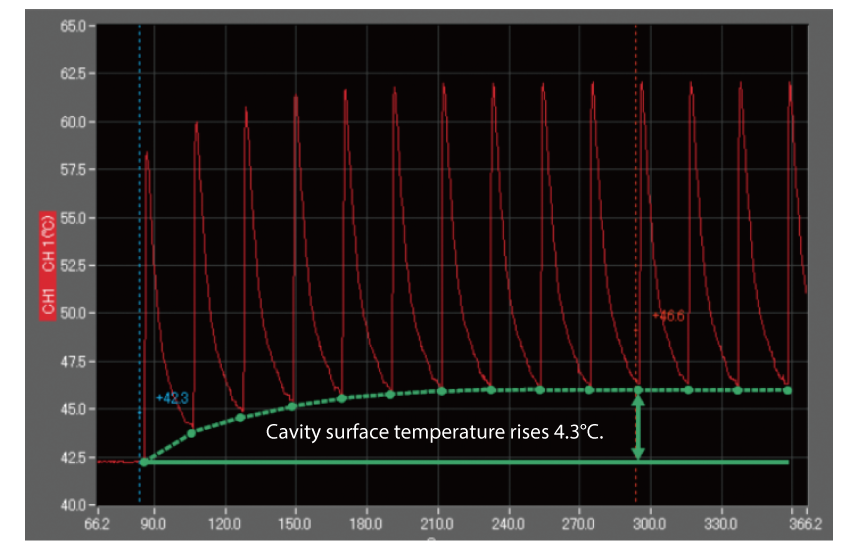

- ・ The cavity surface temperature as of before arrival of resin increased by 4.3˚C from 42.3˚C to 46.6˚C in 10 shots from the start.

- ・ Temperature differences of 2.3 to 6.6˚C between the temperature controlling machine setting temperature and the temperature measured are confirmed at a point very close to the cavity.

Measurement waveform

It is possible to check the temperature of a point very close to the cavity of a mold in real time by displaying the measurement data as a waveform on a commercially-available measurement instrument or data logger. The measurement waveform can be utilized for improvement of molding quality and molding efficiency, including setting the optimum temperature for solidifying resin, minimizing the number of abandoned shots at the startup of molding, and checking the multi-piece mold temperature distribution.

Measurement waveform of mold surface temperature

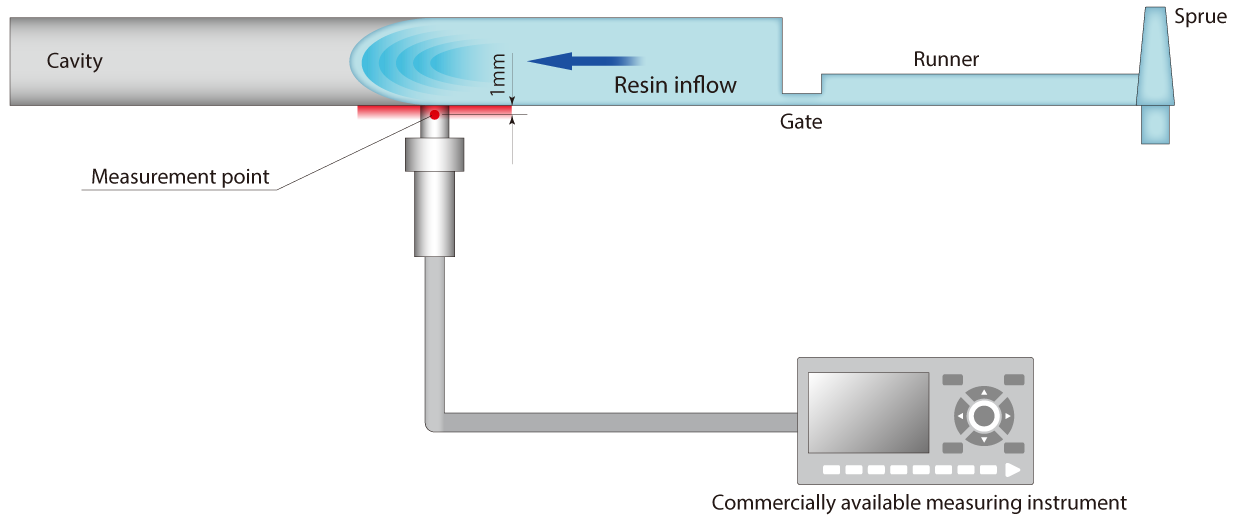

Measurement principle

The contact point whose temperature is to be measured is located within 1 mm from the tip of the sensor. The sensor is installed flush with the cavity surface, and measures the temperature of the point 1 mm away on the mold side from the cavity surface.

Sensor types

Mold surface temperature sensor STF

- As a sensor for injection molding mold, the product boasts a rigid design that withstands a mold temperature of up to 220˚C and resin pressure of up to 150 MPa.

- Due to the employment of a K thermocouple, this product allows a general-purpose temperature measurement instrument and a data logger to conduct measurement, which enables the introduction of the sensor at a low cost.

- With the minimum tip diameter of φ1, the product can also be applied to small-size mold products.

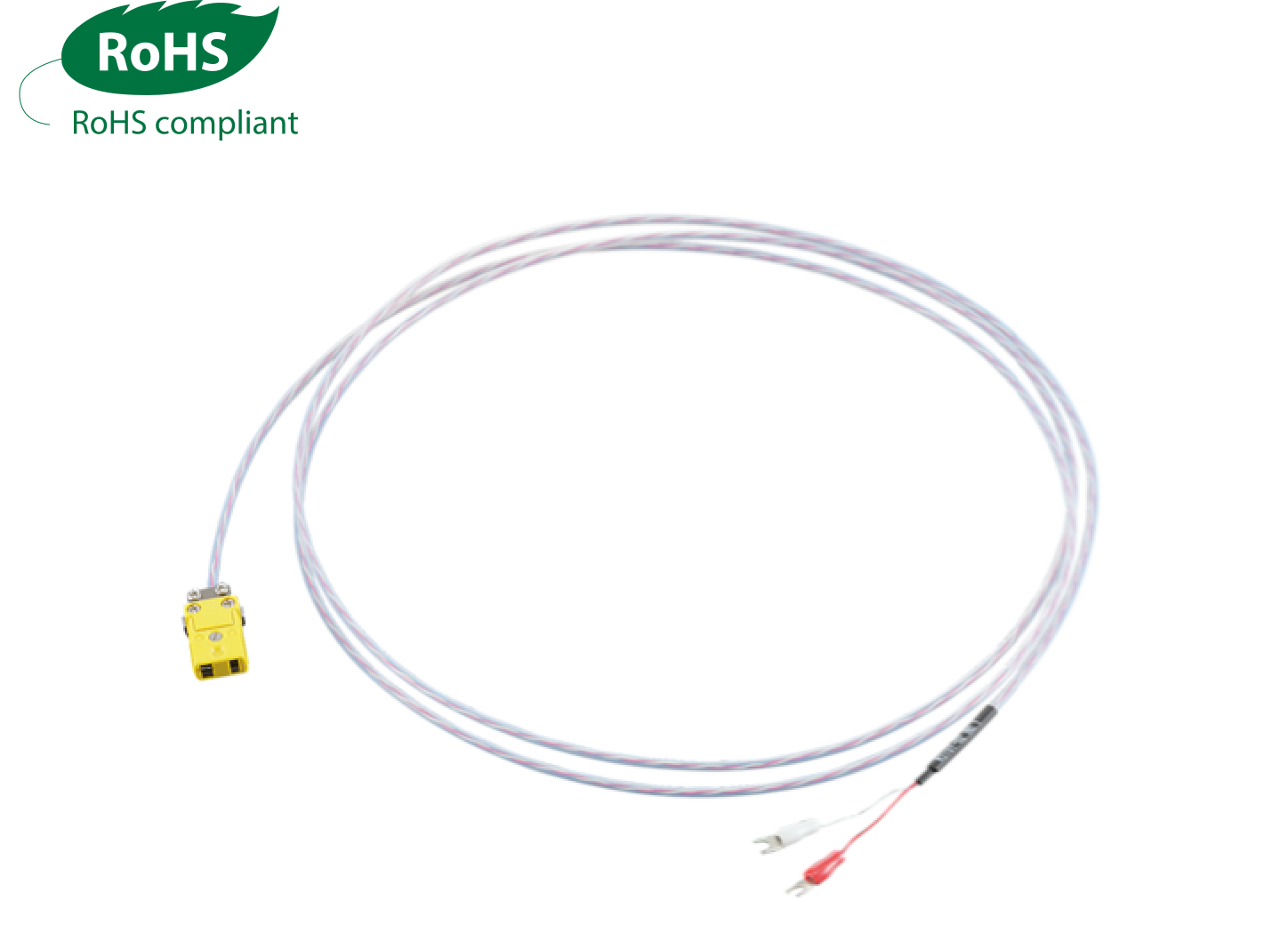

Mold surface temperature sensor adapter cable

- As a K thermocouple-dedicated connectors is employed, the attachment and detachment of the thermocouple does not affect the measurement accuracy.

- As the adapter cable can be separated from the sensor incorporated in the mold at the connector, the adapter cable can be repetitively used.

For detailed product information, download the material from the following link and check it.