In-mold resin temperature measuring system

Advantages of introduction

Optimization of molding conditions including resin temperature

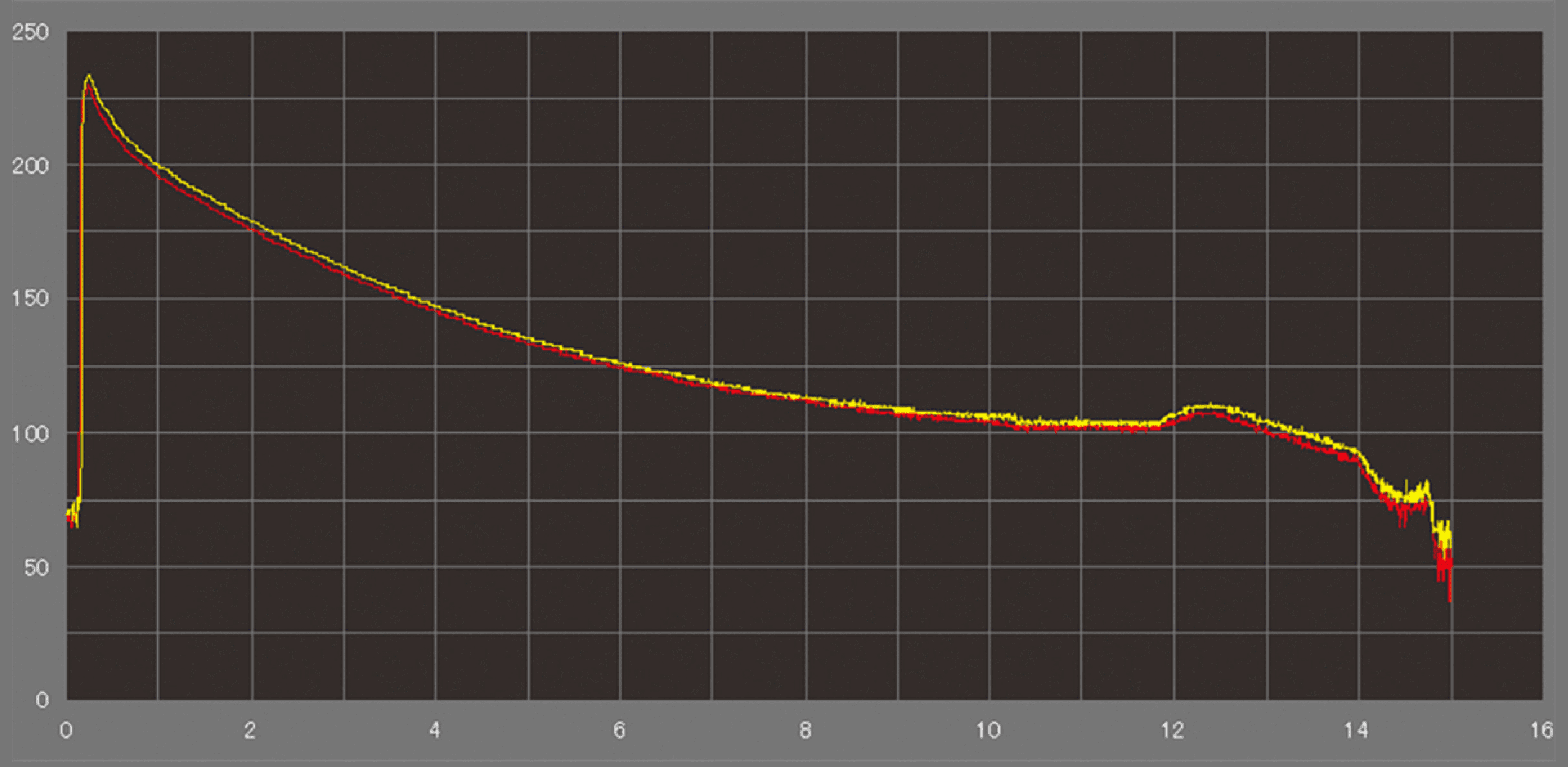

Using the optical fiber infrared ray method, a high response of 8 ms (63.2% response) has been achieved. It is possible to correctly measure the behavior of the in-mold resin temperature, which momentarily changes.

Example of response at high speed of 8 ms (63.2% response) in actual measurement

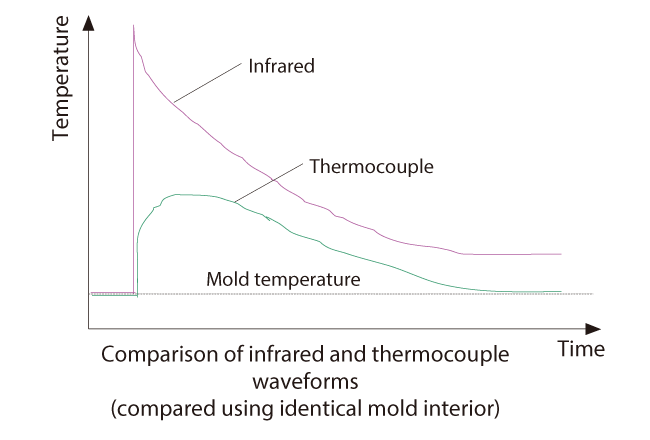

The product has a responsiveness capable of following the resin temperature that changes from moment to moment in a mold. As an ordinary thermocouple has a response of around several seconds, it cannot measure the peak temperature.

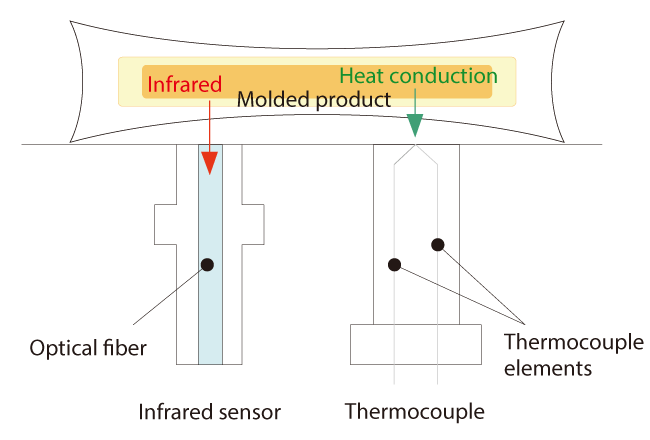

Non-contact temperature measurement (optical fiber infrared ray method)

Unlike contact type sensors including thermocouple, this product can measure the temperature of a mold product even when the resin shrinks and is apart from the sensor tip surface. In the processes from inflow of resin through pressure retention and cooling to mold opening, this product correctly measures the temperatures.

Measurement waveform

It is possible to check the temperature of the resin in a mold in real time by displaying the waveform on a commercially-available measurement instrument or data logger. Using the optical fiber infrared ray method, this product achieves a high response of 8 ms, making it possible to follow the resin temperature that changes from moment to moment in a mold. It effectively optimizes the pressure retention, cooling conditions, nozzle temperature, mold temperature, mold product take-out temperature, molding cycle, and other conditions.

Resin temperature waveform

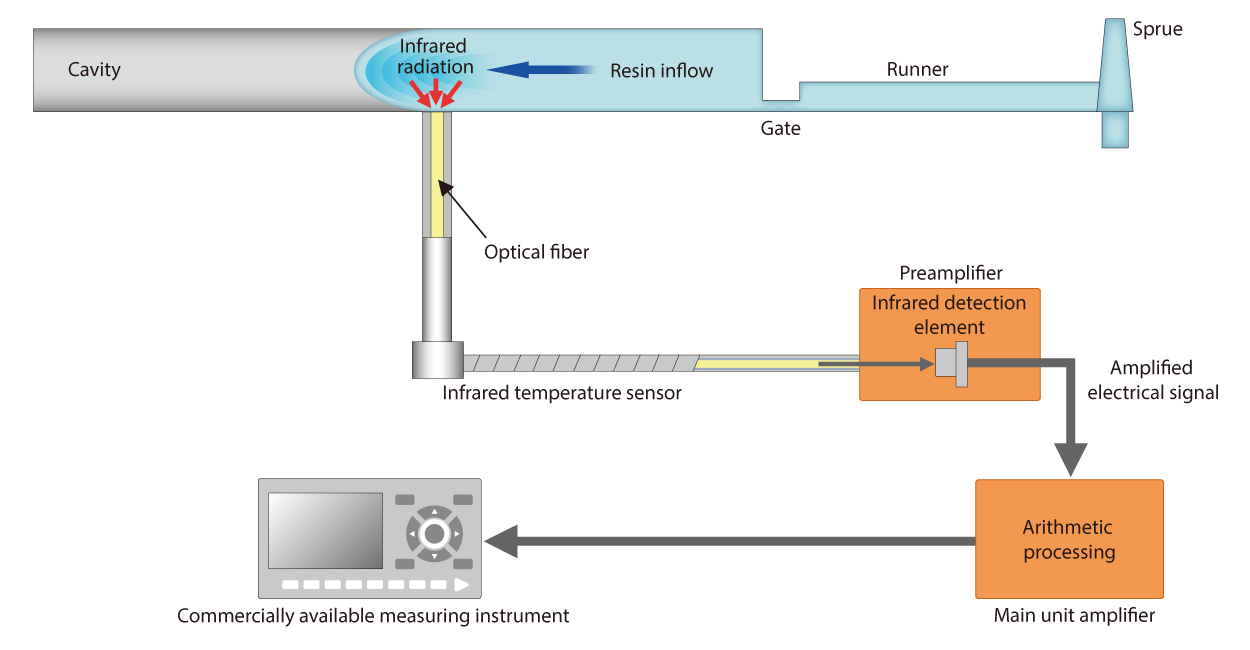

Measurement principle

The product conveys infrared rays emitted from the resin up to the preamplifier via the optical fiber and converts them into electric signals. After conversion, the amplifier performs arithmetic processing and outputs the processing results as temperature signals.

Types of measurement amplifiers and sensors

Resin temperature measurement amplifier EPT-001

- A single product can conduct simultaneous measurement in four channels.

- Capable of outputting 1 V per 100˚C, this product can be used in combination with a general-purpose measurement instrument or a control device.

- 1 msec sampling speed applicable to high-speed filling

- Due to our proprietary sensor sensitivity adjustment system, the need for burdensome calibration work has been eliminated.

Resin temperature sensor – ejector pin type EPSSZL series

- Infrared ray detection type with optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- Resin temperature in the range of 60˚C to 430˚C can be measured.

- The ejector pin shape allows easy incorporation in a mold. (*1)

- With the minimum tip diameter of φ1.7 mm, the product is also applicable to small-size mold products.

*1 Machining such as flange cutting to prevent rotation is not possible.

Resin temperature sensor – flush-mount type EPSSZT series

- Infrared ray detection type with optical fiber

- High responsiveness: 8 ms (at time of 63.2% response)

- Resin temperature in the range of 60˚C to 390˚C can be measured.

- Flush-mount shape that has achieved highly flexible sensor installation position

For detailed product information, download the material from the following link and check it.