Utilization Method

Search by Categories

-

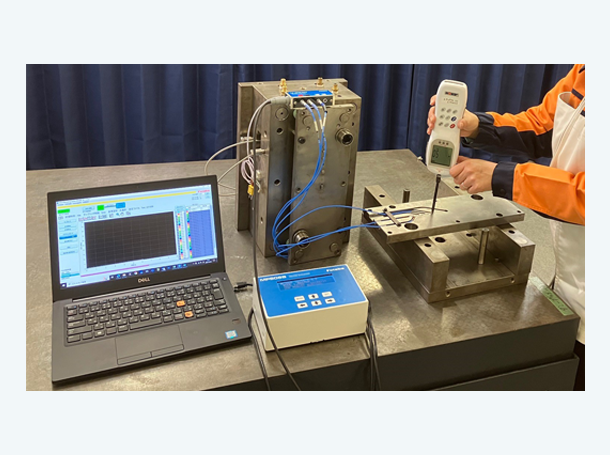

How to check the pressure sensor

Download the materialIn order to correctly measure the resin behavior inside the mold with pressure sensors, it is important to check the functinality of the pressure sensors. Here are 5 check items along with the mold condition, the target pressure sensor, the inspection method, etc. for each item.

-

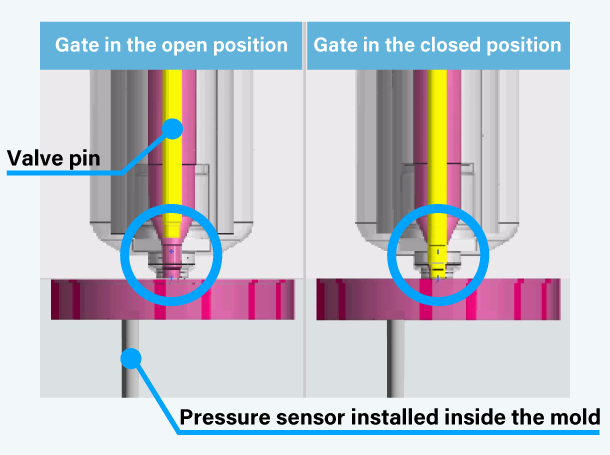

Prevent outflow of defective molded products by automatic detection of valve gate opening and closing abnormalities

Download the materialIn order to prevent the diversion of defective products caused by abnormal opening and closing of valve gate in a hot runner system, it is important to detect opening and closing abnormalities . We will introduce methods for automatically detecting valve gate opening and closing abnormalities using pressure sensors based on measurement examples.

-

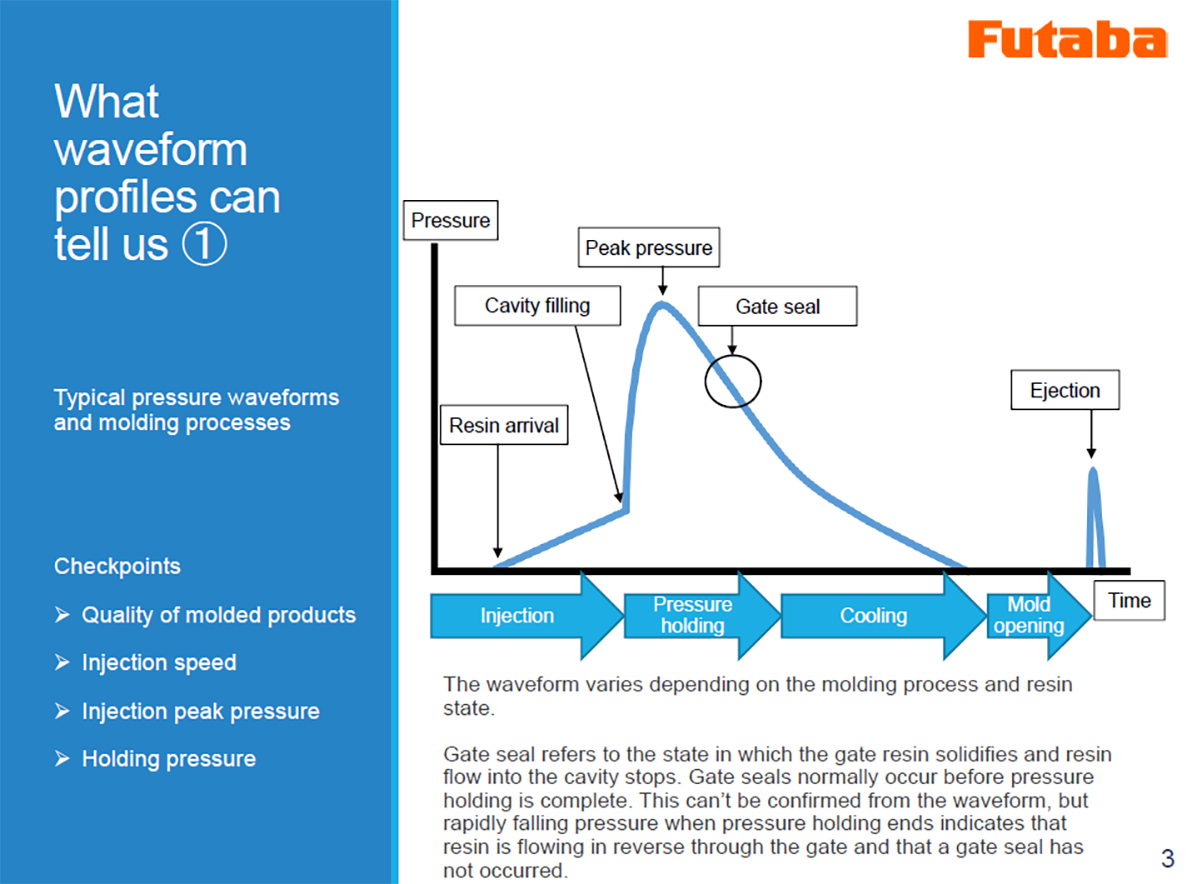

Top 17 matters we can “read” from the pressure waveform shape

Download the materialThis is a material that shows what you can read from a measured pressure waveform and explains the shape of the pressure waveform that varies depending on the shape of the molded item.

-

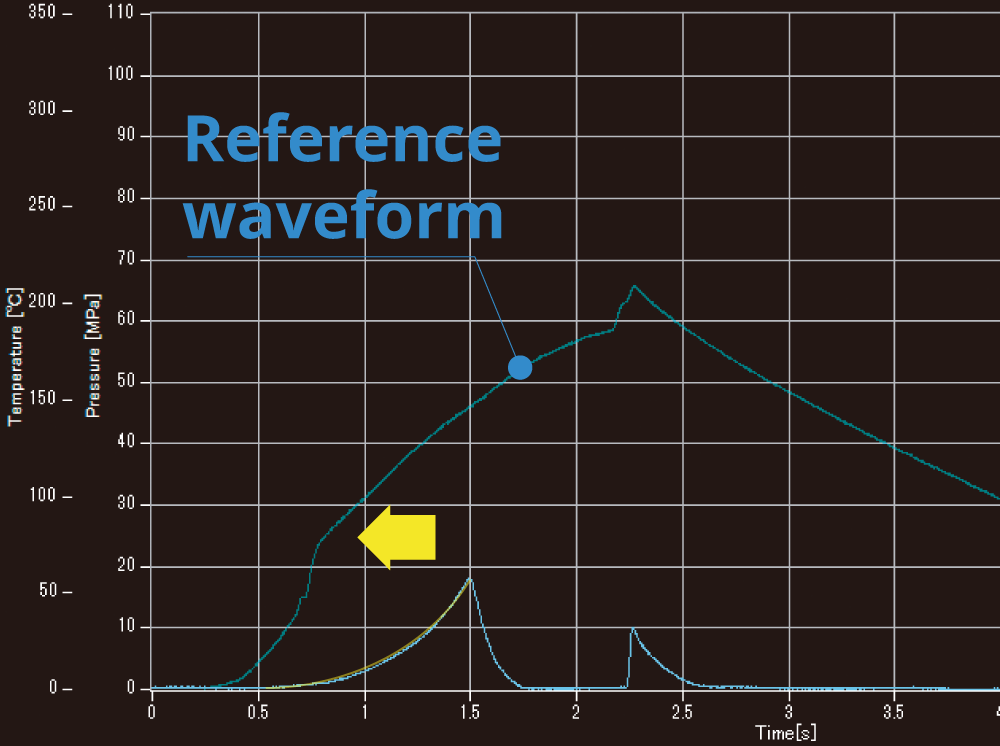

Knacks for reproducing molding conditions through matching with a reference waveform

Download the materialBy setting the molding conditions in such a way that the waveform of the in-mold pressure overlaps with the waveform generated with good product quality (reference waveform), it is possible to reproduce the molding conditions for a good-quality product. This material explains its specific procedures.

-

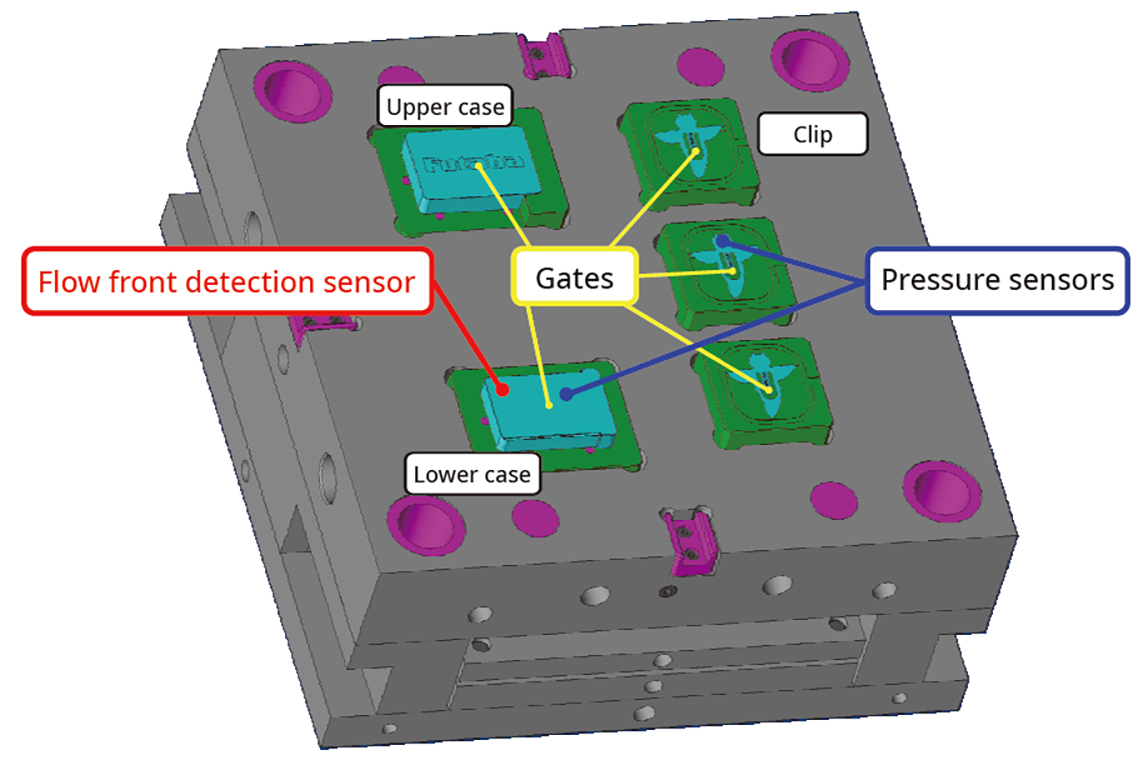

Optimization of opening/closing timing that controls the opening/closing of the hot runner valve gate and quality improvement

Download the materialThis material explains the method of realizing “family mold” with different resin capacities by controlling the opening/closing timing of the valve gate with the pressure sensor and flow front detection sensor serving as a trigger.

-

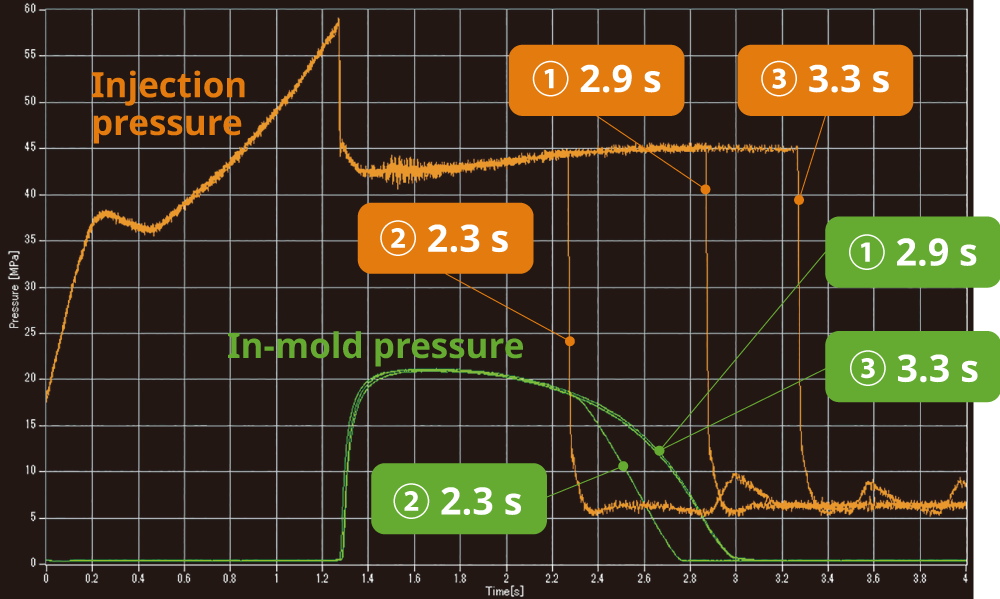

Optimization of V-P transfer timing and pressure retention time through comprehensive monitoring of injection pressure and in-mold pressure

Download the materialThis material explains the method of shortening the molding cycle by optimizing the V-P transfer timing and pressure retention time through comprehensive monitoring of the injection pressure on the molding machine side and the in-mold pressure.